Since the late 1980s we have supplied over 3,500 connectors which are used throughout the oil and gas industry. These connectors can be used in critical and non-critical application and are used for emergency repair, planned shutdown or tie-in, or as part of contingency stock.

Product Description

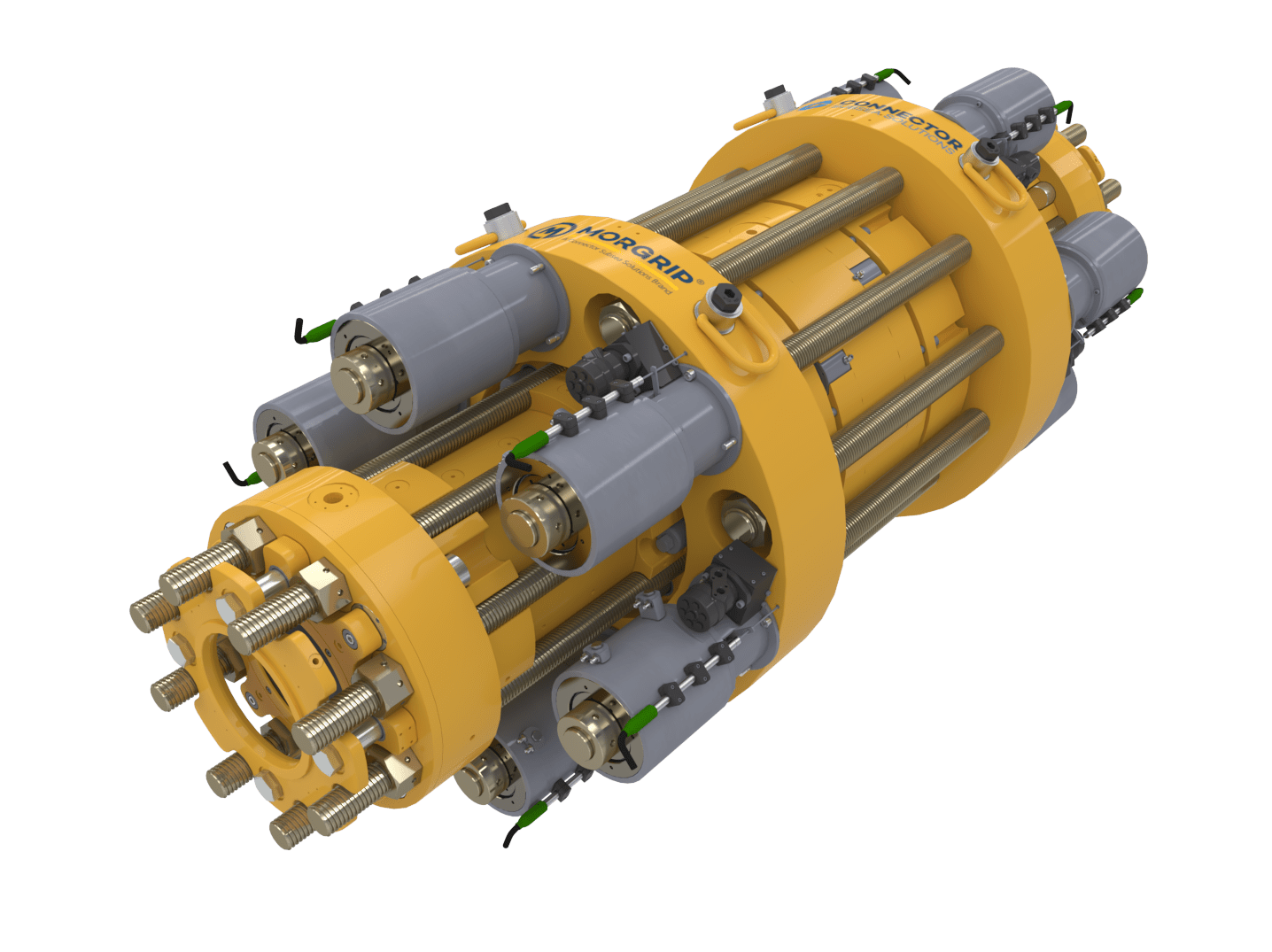

MORGRIP® Subsea Remote Connectors enable subsea pipelines to be joined or terminated in a hub/flange or end cap, in locations that are difficult or impossible to reach by divers.

Developed to be installed remotely, our connectors are field proven throughout the world and we are the only supplier with relevant track record having supplied 95% of all in-service units.

A DNV Type Approved Product, the MORGRIP® enables a certified permanent repair for a wide range of pipe materials, pressures, diameters and temperatures.

The unique gripping and sealing technology ensures a connection that is at least as strong as the pipe itself, outperforming quality welds in fatigue loading.

With over 90 remote units supplied since the 1980’s providing a 100% success during infield operation, MORGRIP® holds the industry records for highest pressure, deepest water location, largest pipe diameter and is the only unit deployed in a vertical riser application at 1350mwd.

MORGRIP® Remote (Deepwater) Connectors

Supplied as Couplings (pipe-to-pipe), Flange Adaptors (pipe-to-flange) or End Caps (pipe termination)

Available for carbon steel, stainless steel or duplex pipe materials

Standard temperature capacity from -40°C to 250°C

Dual graphite sealing technology enabling back seal pressure test to confirm successful installation

Rated for working pressures up to and including ANSI 2,500 lb rating (638 bar)

DNV Type Approval including all key features mentioned, for 1/2″ to 42″ pipeline diameters

Connector Subsea Solutions

Connector Subsea Solutions